Sound Signature

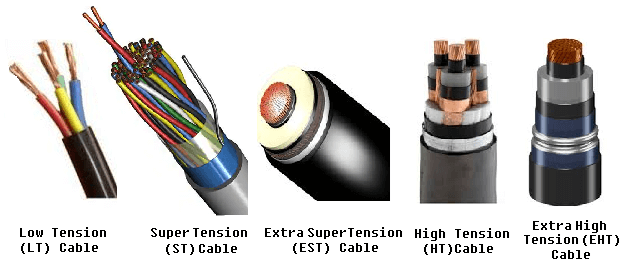

Cables and interconnections are composed of three main elements: the signal conductors, the dielectric and the connectors.

The conductors carry the audio signal, the dielectric is an insulating material between and around the conductors, and the connectors provide the connection to the audio equipment.

These elements are integrated into a physical structure called cable geometry.

Each of these elements, in particular the geometry, can affect the sound characteristics of the cable.

“Heavy Metal”

Conductors are usually made of copper or silver wire. In High-End cables, the purity of the copper is important.

Copper is sometimes specified as having a certain percentage of “pure” copper, with the rest being impurities. These impurities are usually: iron, sulfur, antimony, aluminum, and arsenic.

Generally, the purer the copper, the better the sound. Some types of copper are called OFC or Oxygen Free Copper. This is copper that has had the oxygen molecules removed. It would be more correct to call it “Oxygen Reduced” copper, because it is impossible to completely remove all the oxygen.

Another term commonly associated with copper is LC, or Linear Crystal, which describes the structure of copper.

Copper is not isotropic, it looks different in one direction than the other due to its grain structure, which can be thought of as small discontinuities in the copper.

The use of special melting techniques minimizes this problem.

The other conductive material is silver. Silver cables are obviously much more expensive than copper ones.

However, silver conductivity is only SLIGHTLY higher than copper, but silver oxidizes slower than copper.

Silver also introduces a characteristic sound setting, which is sometimes more tiring.

“The Music is in the Air”

The other important element of an audio cable is the dielectric. The dielectric is the material that surrounds the conductor, and it is what often gives cables some of their mass.

The dielectric material has a BIG effect on the sound of the cable; comparing identical conductors and construction geometries, but with different dielectric materials, demonstrates the importance of the dielectric.

Dielectric materials absorb energy, a phenomenon called dielectric absorption; a capacitor works the same way, basically a dielectric material between two charged plates stores energy.

Unfortunately, in a cable, dielectric absorption can degrade signal quality.

The energy absorbed by the dielectric is released back into the cable slightly delayed in time: an undesirable condition.

Different dielectric materials are chosen to minimize dielectric absorption.

The least expensive cables use plastic or PVC for the dielectric.

Better cables use polyethylene, polypropylene, or Teflon.

In any case, the best dielectric is air (except for vacuum). Different dielectric materials make cables sound in different ways, just as they do in capacitors.